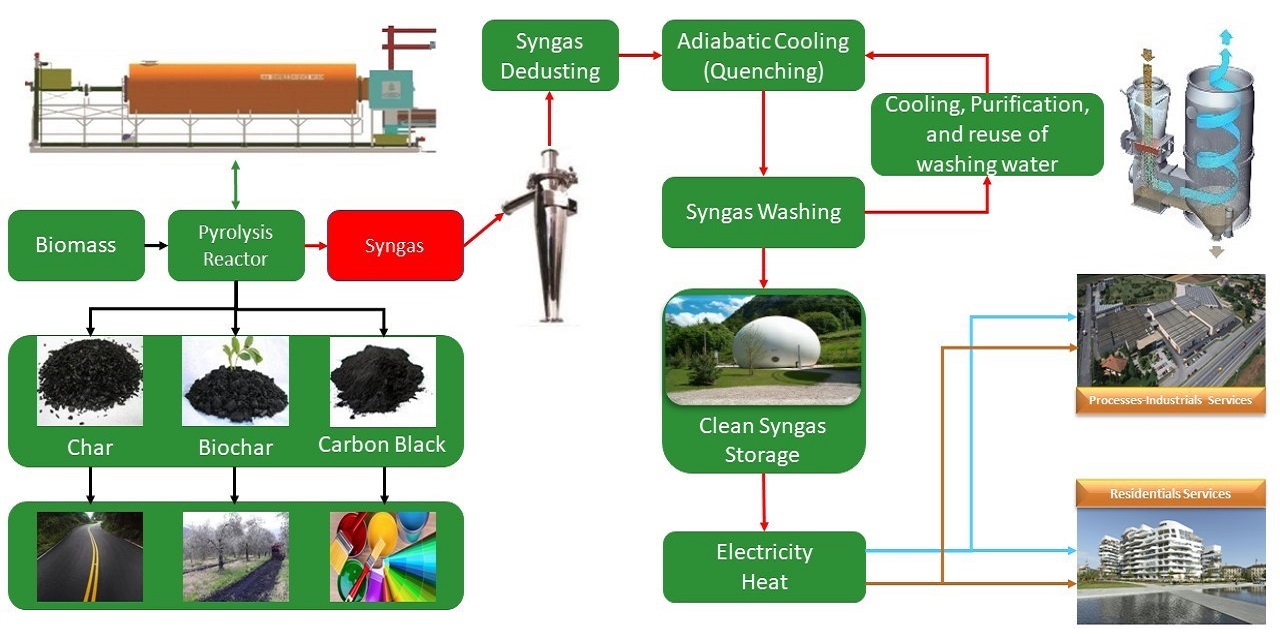

Turning waste into resources and doing it in an ecological way is possible. An adequate pre-treatment of the waste, a thermochemical process without combustion and an adequate treatment of the process products must be used at this purpose. We do this with CARBOGEN® technology.

- CARBOGEN® technology makes use of the pyrolytic transformation of waste.

- You get the transformation of waste into energy products and by-products

- Products and by-products are clean

- Depending on the nature of the treated substance, the by-products are used in agriculture or other industrial applications

- The whole process does not pollute the environment with neither emissions nor residues

- The plant that houses it is energetically autonomous and has minimal consumption of water and other process substances